Former general hand flourishes as leather products business owner

Patrick Chitumba, Midlands Bureau Chief

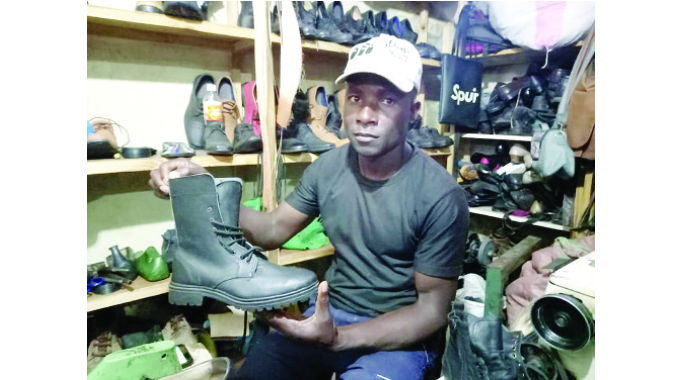

After losing his job as a general hand at G&D Shoes in Bulawayo some 12 years ago, Mr Blessing Moyounotsva (40) was determined to start producing his own leather products.

G&D Shoes closed shop in 2011 and was placed under liquidation, which prompted the father of two to set up a shoe making enterprise.

Mr Moyounostva, who now lives in Gweru, said before G&D Shoes closed its doors, an opportunity to learn how to make shoes and other leather products had arisen within the firm.

He grabbed the opportunity with both hands and was under the tutelage of experts in the field for about six years.

“I was born and bred in Mutare but I went to look for work in Bulawayo before I was engaged by G&D Shoes as a general hand around 2002. After working for some time as a general hand, there was an opening and I started learning how to make shoes and other leather products,” he said.

Mr Moyounotsva said when G&D Shoes closed, he had gained enough knowledge and expertise to start his own business.

“The demise of G&D Shoes in Bulawayo gave rise to many shoe-making companies and individuals like myself.

“We were taught how to make shoes, stitch-by-stitch. We learnt about the processes, which start from cutting upper parts, stitching shoe uppers, lasting and assembly,” he said.

Operating from a small shop in the central business district, Mr Moyounotsva is now a force to reckon with in the leather industry as he has gained popularity for making shoes for both adults and schoolchildren.

He makes handmade safari and outdoor footwear as well as leather accessories.

“After working for the company for about six years, I told myself that I was not going to be employed by anyone.

“Using some of the money I got as a package, I bought my first machine but the journey has not been a rosy one. I have no regrets though because I’m able to look after my wife and two children,” said Mr Moyounotsva.

He said it was a challenge accessing raw materials as they are expensive and always in short supply.

Mr Moyounotsva said a square foot of processed hide costs about US$4 while shoe soles cost about US$7.

“With all the raw materials available, I can make an adult shoe in less than three hours. It’s because of the experience I got from G&D Shoes.

“With the experience I now have, I can make at least four pairs of shoes a day. I also make wallets, bags and repair customer’s leather products,” he said.

Mr Moyounotsva said he bought a second machine as he seeks to grow his business and employ other people.

He called on financial institutions to avail affordable loans for small to medium enterprises so that they grow to become big companies.

“There’s need for the recapitalisation of the leather industry as a whole and that is possible if we have access to cheap loans,” said Mr Moyounotsva.

“We look forward to the Government assisting us with finance for recapitalisation. I want to penetrate other towns and cities and God willing, regional markets.”

Mr Moyounotsva bemoaned the cost of raw materials and lack of working capital which he said continued to weigh down efforts to boost production to meet the rising local demand.

“We’re also competing with low-quality shoes and other leather products that are flooding the market.

“That is not good or viable for us in the leather industry,” he said.

Mr Moyounotsva said profit margins are affected by high production costs, such as electricity, labour and raw materials.

Some of the shoes

“The cost of raw materials is high and remember one has to factor in labour, electricity and other costs related to running a successful business.

“The prices of my shoes start from about US$10 going up depending on size and type. But at times, I’m forced to negotiate with clients. At the end of the month, I’m able to pay rentals at the shop, at home, and look after my family,” he said.

Mr Moyounotsva said there are many challenges affecting the leather industry, among them poor quality of hides that in turn affect the prices.

“There are challenges that come with operating any business but it is up to us as Zimbabweans to consider using our hands for the betterment of our lives and the country at large.

“Every day I wake up knowing that I have to use my hands to make money to look after my family. No one will do it for me,” he said.

Cabinet in 2021 approved the new Zimbabwe Leather Sector Strategy 2021-2030 which is anchored on increased investments and maximising on value addition and beneficiation to promote export-led industrialisation.

The leather sector is regarded as a low-hanging fruit for the Zimbabwean economy given the country’s comparative advantages in livestock and crop production, which provide key raw materials.

The strategy, which is a successor to the Leather Sector Strategy (2012-2017), seeks to increase the overall competitiveness of the leather value chain in Zimbabwe and enhance access to both local and export markets for the finished products.

The major objectives of the leather strategy include improved access to finance throughout the value chain so as to buttress the sector players’ cash flows, improved market intelligence of all enterprises and stakeholders and improve quality and collection of hides and skins.

According to the Zimbabwe Leather Development Council (ZLDC), a review of the first leather strategy was done and showed minimal results as the sector faced numerous challenges, mainly from the challenging macro-economic environment.

Comments