Varsity raises innovation bar. . . Hearing aids made by MSU

Patrick Chitumba – [email protected]

The pace-setting Midlands State University (MSU) has ventured into the production of hearing aids as it continues to set itself apart as an innovative institution of learning.

Hearing aids also known as earmolds are a useful tool which amplify sound or protect against it.

They are custom made and have a specific function, depending on what the wearer’s needs are.

The device itself is usually inanimate; no power source or controls are installed. If one were to observe it, it would look like a small plug that fits exactly into the wearer’s ear canal.

The hearing aids are being produced by the university’s Special Needs Services Unit under the National Language Institute (NLI) which is making Education 5.0 a living reality for members of the society.

Under Education 5.0, Zimbabwe’s state universities must launch into outcomes-focused national development activities towards a competitive, modern and industrialised Zimbabwe.

It is now all about problem-solving for value creation.

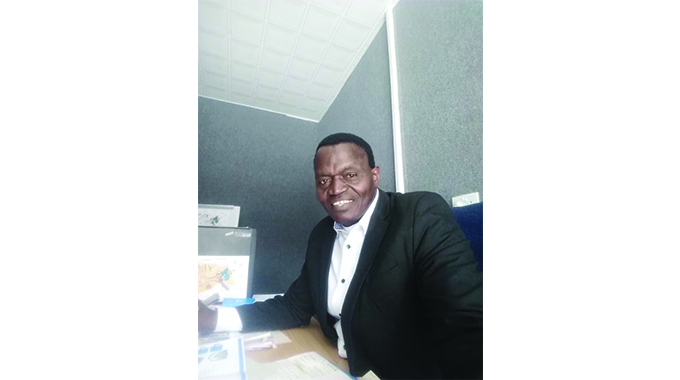

Mr Rwakonda and a happy 83 year old client with an earmold

The NLI was established in 2018 to carry out language research and provide language consultancy services in the country and beyond.

After only three years of existence, the language centre was commissioned by President Mnangagwa on November 26, 2021, to become the MSU NLI.

The centre is made up of four units namely the Language Consultancy and Services Unit, Special Needs Services Unit, Language Technology and Digital Services Unit and Foreign Languages Unit.

Special Needs Services Unit Researcher Mr Sebastian Rwakonda said the department is now making earmolds for amplifying sound.

“The Special Needs Services Unit under the National Language Institute at the MSU has achieved another milestone as it is now making earmolds for amplifying sound, commonly known as hearing aids,” he said.

Mr Rwakonda highlighted that the Special Needs Unit also provides Sign Language and audiological support services.

He indicated that they have an Audiometric testing room for carrying out hearing tests for clients who need the service no matter where they are coming from, within or outside the Midlands province.

Mr Rwakonda grinding the earmould to size

“The results of the Audiometric tests will determine the kind of services one requires. In the case of those with profound hearing loss, Sign Language training can be provided through a Sign Language Short Course,” said Mr Rwakonda.

He added: “Even those without hearing problems but in need of enhancing their communication skills in Sign Language are welcome since this resonates well with the spirit of inclusivity. We also do video recording and translation of documents in Sign Language for the benefit of people with hearing impairment.”

Earmould attached to the hearing aid ready for use.

Mr Rwakonda said the materials used to build an earmold are confined to soft types, which are silicone and vinyl, and hard types, which are lucite and acrylic.

Some earmold manufacturers have a proprietary blend of several of these materials. Softer materials are employed when the earmold is used to protect hearing, or when the wearer is bothered by hard materials in their ear.

“In terms of assistive technology for hearing impaired people who use hearing aids, the Institute has an earmold production section where custom made earmolds are produced at the shortest possible time of not more than 45 minutes using the latest technology,” he said.

MSU language institute

Mr Rwakonda said instead of going to far away centres when one is in the Midlands province or anywhere around the province, one would save valuable time by visiting the NLI for such services.

“We want to be the sole supplier of custom made earmolds for our clients nationwide and even beyond our national boundaries. We have the capacity to provide hearing aid fitting and repair services,” he said.

Mr Rwakonda who has vast experience in audiological practice and has worked as an Audio-Lab technician for more than 20 years said they had also embarked on braille production.

Mr Sebastian Rwakonda

“The other section of the Special Needs Unit deals with production of Braille material for people with visual impairment. We have managed to produce brailled documents for the Government through the use of our state-of-the-art equipment, Fanfold DV5 Embosser. These documents include the National Development Strategy 1(NDS 1), Compendium of Projects by the Second Republic, Consumer Protection Act, and Disability Policy to mention a few. We have the capacity to deliver on any assignment given to us using available local resources and expertise,” he said.

Mr Rwakonda said the unit seeks to serve marginalised people including people with disabilities, particularly those with hearing or visual impairments which require specialised services that are expensive or not readily available.

“We don’t want people to suffer when we are there due to non-availability of services or products and cost implications which see them being excluded in development programmes. Remember at some private centres, they don’t cater for clients from outside their school boundaries due to resource limitations hence our coming in to close the gap,” said Mr Rwakonda. – @pchitumba1

Comments