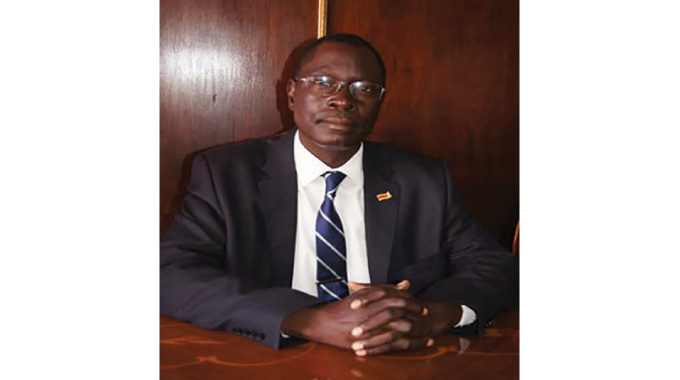

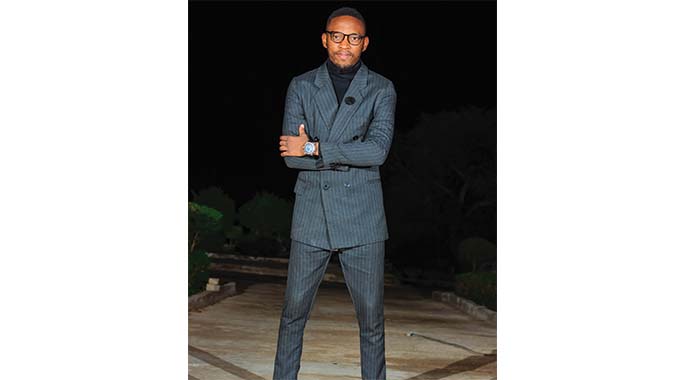

Roland Nyathi, the self-driven tailor

Kamangeni Phiri

Most unemployed youths who go to panning sites in the gold-rich district of Gwanda are there to eke a living.

But Mr Roland Nyathi is not your average youth.

When panning sites and small-scale mines are operational, he goes there as a tailor of note to market his work suits and T-shirts.

“We cannot all be gold panners, teachers or farmers,” says the soft-spoken entrepreneur. “People need clothes so someone has to make them.”

His quest to be unique saw him sell his only car in 2017 to raise seed capital for his tailoring business.

Many dubbed the strong-willed Mr Nyathi a “clueless gambler” but he was undeterred.

“No one believed in my dream then since I had no tailoring experience or knowledge,” he said. “But I am one person who believes in himself”.

After selling his Mazda Familia, he bought two industrial sewing machines, an overlock and straight machine.

His is a story of self-belief, confidence and hardwork that is in sync with the Second Republic’s push towards establishing an upper middle-income economy by 2030.

Today, Mr Nyathi’s shop, Livery Fashions, has become one of the top uniform and T-shirt manufacturers in Gwanda.

The shop supplies school uniforms, sportswear, work suits, domestic workers’ uniforms, African attire, T-shirts and T-shirt printing.

“Livery means uniforms. I came up with the name because I wanted it to reflect on what we do best, which is sewing quality uniforms.

Most companies, schools and individuals in Gwanda now know that if they want quality uniforms, our place is the go-to-shop,” he said.

Mr Nyathi’s relatives were initially skeptical about the tailoring business. They were wary of the competition posed by cheap imported clothes at flea markets.

But they have since warmed up to the project.

“We had just closed our flea market because the business was no longer viable. It was a bit difficult then to buy into the idea of starting a tailoring business,” said his wife, Mrs Belinda Nyathi nee Moyo.

Today, Mrs Nyathi is the face and buyer of Livery Fashions.

“Customers first see me. I take orders and make quotations. I also check on our material stock. If the material is not enough I place orders with our suppliers who are in Gwanda, Bulawayo and South Africa,” she said. The couple has five kids.

Mrs Nyathi, who is an entrepreneur in her own right, converted one corner of the shop to a boutique where she sells South African clothes and shoes that she buys online. She also plaits and styles women’s hair from the same shop.

Mr Nyathi has never been one to take the easier route in life. Way back in 2006, just a month after completing his Ordinary level exams, the young entrepreneur packed his bags and left his rural home for Botswana to work as a herdsman.

This was despite being a son of a successful farmer who owned a large herd of cattle and two trucks.

“It was absolutely crazy,” recalls Mr Nyathi who at 34 has already racked up an impressive resume that includes managing a jewelry shop in the heart of Johannesburg in South Africa and owning a uniform making shop in Gwanda town.

“I did not know anyone in Botswana but again, I did not want to be home lest I got tempted to pan for gold.”

Six months later, in July, 2006, Mr Nyathi returned home to collect his Ordinary level results.

He passed four subjects and immediately decided against improving his certificate.

Mr Nyathi, who was aged 19 then, packed his bags again in September and headed to South Africa.

The South African experience marked the genesis of his business acumen and sound managerial skills.

He started by doing odd jobs before his breakthrough came in 2010 when he got employment at a jewelry shop.

Six months down the line, the owner identified him for grooming as a manager.

He ended up managing the shop but voluntary resigned in 2012.

Mr Nyathi came back home armed with some business plans that he wanted to implement.

“Before leaving South Africa, I bought a laptop, camera, picture printing machine and eight cell phones. I sold the phones and used the money to open a flea market in Gwanda,” he said. While selling clothes he also worked as a street photographer.

In 2013, Mr Nyathi opened a shop in town where he would load music on memory cards and phones. He turned part of the shop to a studio for shooting passport and driver’s licence photos.

“Business was now low at the flea market and I decided to close it. I had to focus more on the shop-cum-studio,” he said.

At that time, Mr Nyathi was staying with his parents at their rural home in Nkashe area, Chief Masuku, 27km out of town. He was commuting daily to town.

“Staying in rural areas helped me get additional business in the form of covering weddings and other social events. It was while I was taking photos that some rural and urban schools introduced IDs.

They approached me to take passport size pictures of their pupils and design the IDs,” said Mr Nyathi.

From the schools IDs project he raised enough money to buy a car, two heavy duty photocopying machines and a printer. He started offering typing and photocopying services.

“I then thought of looking for accommodation in town. My workload had more than doubled and was knocking off late after starting very early. I was the only one offering typing services in the whole town.

Many students, especially from JMN Nkomo College, would regularly come to me for typing and photocopying services,” said Mr Nyathi.

He started employing to ease the pressure.

Mr Nyathi’s business kept growing and he ended up owning six heavy duty photocopying machines, 10 laptops and seven employees.

“I also had three cameras for taking ID pictures and covering events. We moved to a bigger place at Akjet Mining Complex,” he said.

Around 2016, more people came into the photocopying business giving Mr Nyathi serious competition.

It was then that he thought of diversifying into T-shirt printing and he bought the relevant machine, leading to the establishment of Livery Fashions in 2017.

“I would buy T-shirts in Harare, print and then sell them. My customers were also bringing in their own T-shirts for printing. This gave me the idea of making my own T-shirts.

This is when I sold my car and bought the industrial overlock and straight machines. I also won a tender to provide t-shirts to the local municipality and that helped in setting me up,” said Mr Nyathi.

His first two machines could do full sets of uniforms, attires, and work suits but neither could do T-shirts.

“My initial plan was to buy a T-shirt making (flossing) machine, but then you need an overlock and straight machine to complement it. I bought the flossing machine four months later,” he said.When he bought his first machines, Mr Nyathi had no knowledge of tailoring.

He only mastered the art at the end of 2019 after three years of self-coaching and observing.

“I hired two T-shirt making tailors from Bulawayo who would come for two days or one week to work for me. Secretly, I was learning from them but they had no idea they were teaching me.

My only challenge is I cannot sew school uniforms. I have two tailors who do uniforms only,” he said.

One of the school uniforms’ tailor, Mr Trust Mhosva, 30, said their products were popular because “of Mr Nyathi’s dedication to professionalism and quality.”

“We get really busy here especially during back-to-school time. I focus on school uniforms only and Mr Nyathi does the most work. We work as colleagues but I am conscious to the fact he is also my employer who demands quality results,” said the self-taught tailor who has 13 years experience in the field.

Mrs Promotion Hlatshwayo, a customer and teacher at Sibula Primary School, under Chief Mathema’s area, rates Livery products and services highly.

“Mr Nyathi’s customer care is excellent. He is a very good tailor whose work is so neat that one might think the clothes are imports.

The Livery team is professional and courteous. This is why we even have a Livery Fashions WhatsApp group that helps link us with the shop. If you want the best go to Livery,” she said.

Livery Fashions makes an average of 500 uniforms, 240 track-suits and 1 500 or more T-shirts per month, according to Mr Nyathi.

He hopes to move to the industrial areas in future as he projects his business’ growth.

“I am one person who plans ahead. Whenever I plan my things, I don’t expect immediate returns, I do my things in such a way that the project will continuously give me money for five or more years,” said Mr Nyathi as he urged fellow youth to pursue their dreams.

Where there is will there is indeed a way.

Comments