Harare Poly discovers biodiesel from algae

Virimayi Nzira and Collins Mundondwa

In a research breakthrough that could reduce the country’s fuel challenges and promote the growth of other forms of aquatic life, Harare Polytechnic’s Bachelor of Technology department has found means of extracting biodiesel from algae in line with international practices.

Bio-diesel extracted through a process called transesterification, has been tested and complies with B100 specification requirements.

The research comes at a time when the Ministry of Higher and Tertiary Education, Science and Technology Development is promoting the uptake of courses that incorporate Science, Technology, Engineering and Mathematics (STEM) concepts.

STEM seeks to create a dynamic future for Zimbabwe by producing a critical mass of graduates that are empowered to create or recreate industries and future markets.

A lecturer in the Harare Polytechnic B Tech department, Mr Damascus Masawi said the process of making biodiesel from algae starts with the collection of algae from lakes, dams or rivers so that it can be grown in a photo-bioreactor which is aerated in order to provide carbon dioxide to facilitate growth.

The resultant biomass is harvested after 24 days before it is dewatered and allowed to dry.

Oil is extracted from the dried biomass by use of an organic solvent and is converted into diesel through a process known as transesterification which uses alcohol and a hydroxide as a catalyst.

Diesel extracted from algae is an example of a second generation fuel produced from biomass or waste.

First generation bio-fuels such as ethanol and Jatropha bio-diesel are extracted from sugars and vegetable oils found in arable crops which require plenty of growing space but second generation fuels though harder to extract, do not require agricultural land.

The transition to second generation bio-fuels such as micro algae can contribute to the reduction of land required for production since growth of algae only requires a small space.

The process is quicker compared to that of producing first generation fuels. Micro algae takes about 24 days to harvest and its yield per acre is 30 times higher than Jatropha plants – which need about two to three years to harvest.

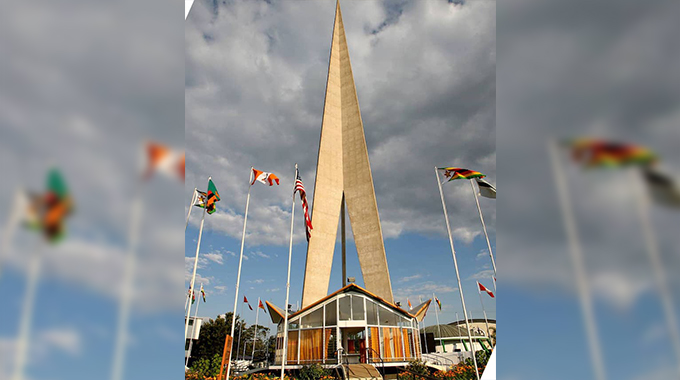

Harare Polytechnic exhibited this green energy solution at the recently held Zimbabwe International Trade Fair (ZITF) where it drew a lot of interest from the public.

Environment Management Agency (EMA) educational and publicity manager Mr Steady Kangata said the research needed to be pursued describing it as a noble initiative.

He said EMA’s wish was to engage researchers so that they can continue to come up with other similar solutions to problems affecting the environment.

The institution has since acquired a one year provisional patent to implement the project based on the findings of the research.

Previously, the Harare Polytechnic B Tech department has participated in other researches that have been implemented at national level.

In 2004, the Reserve Bank of Zimbabwe commissioned a biodiesel project at the Harare Polytechnic under which it procured a test vehicle, bio-reactor chemicals and other logistical support facilities, culminating in the “convincing” certification that biodiesel was a feasible option for Zimbabwe.

Comments